Building project for sustainable stables

New construction of a future-oriented and sustainable animal husbandry facility for pigs with environmentally friendly electricity production

The challenge in planning the new type of pig fattening barn was especially to develop an appealing architecture for the multiple uses. It is important to adapt the overall facility on the property to the prevailing slope and still ensure that the complex integrates into the already existing farm image.

For the sustainability of the project, the planned photovoltaic system also had to be accommodated, which also affected the orientation of the fattening house. In addition, the total number of animals was to be divided into four housing units. However, these barn units need spatial connections for housing and unhousing.

Straw management requires that a storage facility be created. Furthermore, the straw is to be mechanised and transported to the individual stables via conveyor belts and straw robots. Therefore, in addition to the four stables, a fifth complex in the same style is being built here - the straw storage hall.

In order to ensure that other required ancillary rooms do not appear separately as buildings , the hall was supplemented with the ancillary rooms for fodder storage as well as the changing rooms, sanitary facilities and recreation rooms for the staff.

Of course, this modern way of keeping stables also requires technology. A lot of technology. And this building technology, especially ventilation and air filter technology, should of course be as invisible as possible in its entirety through the architectural implementation.

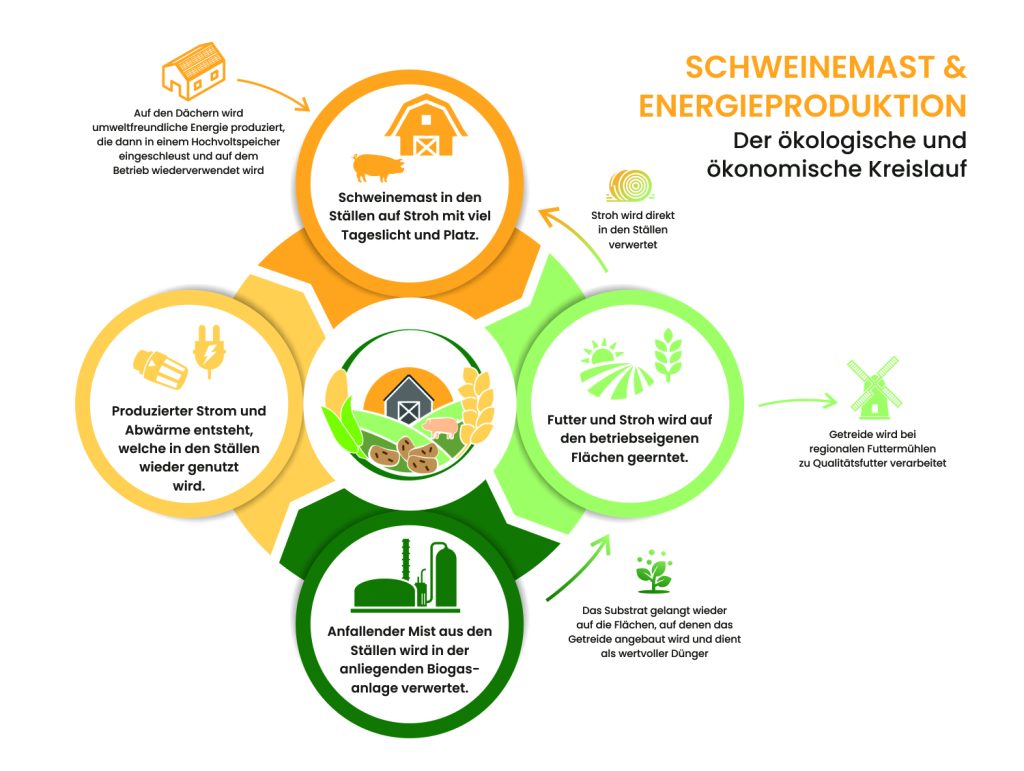

In order to finally implement the sustainable utilisation of the manure produced, a 99kW biogas plant is being built in the form of a farm power plant. This plant is operated exclusively with liquid manure and dung, which in turn produces electricity and waste heat.

Some of the electricity generated is then later stored in a high-voltage storage unit and used for ongoing operations. The resulting substrate from the biogas plant is spread again on the farmland as valuable fertiliser.

Follow our building project from start to finish

Initial discussions on the idea of the project have taken place.

After project presentations and talks with partners such as Bröring, the concrete planning for the stable construction begins.

We start planning the construction of the biogas plant and the PV system. In addition, first ideas for electricity storage are collected.

After a long preparation, we submit the building application. Now we have to wait.

We are delighted to learn that the building application has been approved. The ground-breaking ceremony is planned.

The measurements of the barn buildings and the central corridor are in progress. In the course of March, excavations for tanks and filter buildings will be carried out.

On 30 March, the construction of the biogas plant begins. At the same time, the material is delivered on time.

The first container, the final storage facility for the biogas plant, is built.

Construction company Anton EIken starts with the first works.

Start of access roads and main driveways were provisionally prepared, assembly works on the biogas plant were also continued.

From now on, the TRAFO is supplied with its own line and is thus connected to the grid. The construction site is now supplied with its own electricity.

The first stables of the total of four were scaffolded, the work safety plays a very important and decisive role

Residual works on the biogas plant, such as the assembly of the supporting air roofs or installation of the pump station and pipelines were carried out.

Now it's "Merry Christmas" - even a break must be sometimes, the construction rested during this time.

The time has finally come and the topping-out ceremony is solemnly performed. In the best weather, the building has received a traditional topping-out wreath.

The assembly work on the exhaust air scrubber is in full swing, but the assembly work in the buildings is also in full swing.

At the end of April, the connecting pipes will be laid - it resembled a pile of spaghetti 🙂

Road construction begins, pipes and sewer lines are buried in the ground. Now the finishing touches are being made for the road construction.

The exterior will be spruced up a bit, and the earthen wall around the site will also be created.

The exterior will be spruced up a bit, and the earthen wall around the site will also be created.

The assembly work on the interior of the four stables is completed, now the feed kitchen and water supply and distribution are installed and assembled.

The straw storage hall is erected, in parallel the premises on the 1st floor for conveying the straw to the compartments and conveying equipment are installed.

June was turbulent. Among other things, the bale shredder was placed in the straw hall. In addition, preparations for road construction and exterior work went into the finishing touches. Topsoil was applied and minor beauty work was done.

Inside, the electricians and façade builders had to go all out again, and it was like being in a pigeon loft.

The final work is in full swing and the opening is imminent. Among other things, the outdoor areas are being asphalted and paved.

The big day has come, the opening of the facilities! After a total of almost 5 years of planning and construction, we can now proudly put the new facility into operation. The construction project was inaugurated with many guests from politics, administration and companies as well as neighbors, friends and employees.

The project is now officially up and running, and you can find all further information in the "Pig fattening" and media library sections or on Instagram or Facebook.